Easily Balance Demand and Supply Throughout Your Supply Chain

NetSuite Demand Planning supports both demand and supply planning capabilities. NetSuite Supply and Demand Planning helps balance supply and demand in a way that provides businesses the right combination of cost control, accurate lead times and service level. Using inventory management and demand planning techniques combined with a robust scheduling engine and predictive analytics, NetSuite Supply and Demand Planning helps businesses to make informed decisions which ensure product availability while keeping excess inventory to a minimum.

Demand Planning

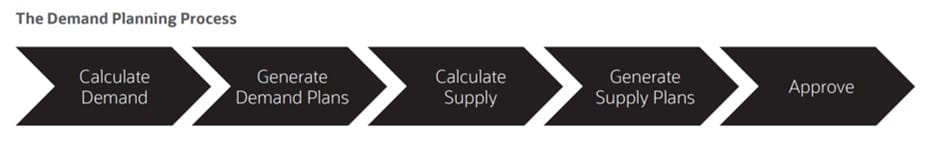

NetSuite Demand Planning predicts future inventory needs based on historical demand, seasonality, open opportunities and/or sales forecasts. The demand planning process includes calculating demand, generating demand plans, calculating supply, generating supply plans, and finally executing purchase orders, transfer orders and work orders. By pinpointing when to reorder items and in what quantities, you can optimize stock levels, improve forecast accuracy, and enhance supply chain planning. NetSuite Demand Planning ensures you have the right amount of stock on hand to fill orders without having overstock sitting idle on warehouse shelves.

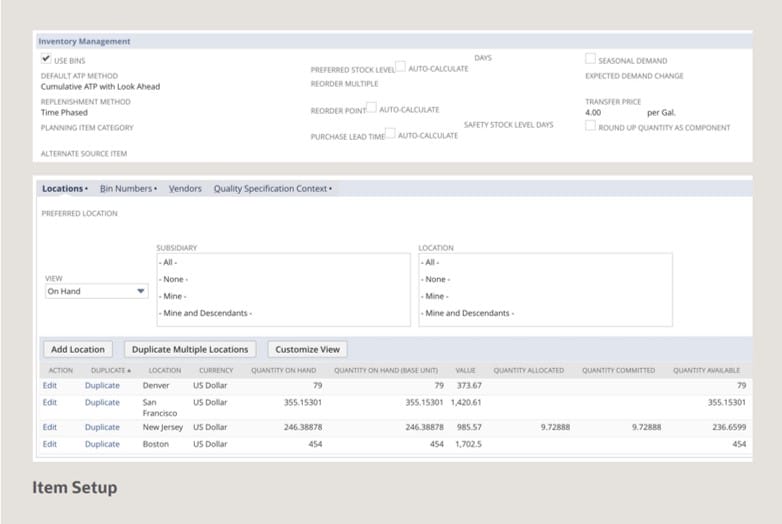

Item Setup

One of the most critical areas to the planning process is defining the parameters that affect each item. This defines the item as being available to demand planning, establishes an alternate source item (if you are trying to plan a new item with no sales history), and establishes which distribution network and category it might belong to if you are using the DRP (distribution resource planning) functionality so that you can transfer inventory between locations. You can also set additional planning parameters that affect either how demand is evaluated or how the planned orders are generated.

Forecasting

With the demand planning process, demand can be evaluated and presented in a number of different ways including:

- Linear Regression – Use previous demand to project future inventory based on the ordinary/least-square regression method.

- Moving Average – Use the moving average of historical demand to calculate the overall average stock level needed and then project future stock levels using that overall average.

- Seasonal Average – Use previous demand to examine the seasonal trend of inventory flow and then project a similar seasonal trend for future stock levels.

- Sales Forecast – When using NetSuite for your sales operations, this option uses forward looking sales forecast data (such as opportunities, estimates, etc.) to project inventory demand.

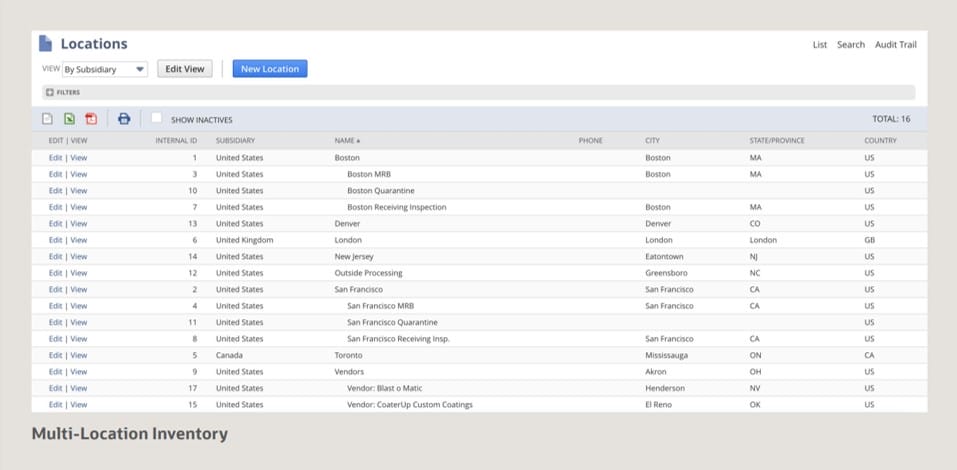

Multi-Location Inventory

Easily define multiple inventory locations with real-time visibility. Locations can be organized hierarchically—for global businesses the country can be defined. During the planning process, the system can be set up to automatically create transfer orders between locations as necessary.

Allocation Exceptions Management

To respond to supply shortages and VIP customers, you can review all sources of supply and order allocations to ensure that high priority sales orders ship complete and on time. To minimize the effect on all orders, the system provides intelligent supply reallocations recommendations designed to take the resources from multiple unallocated orders and fulfill priority orders first. It can also generate alternate recommendations, reducing the time to find, review and execute reallocations and automatically re-aligns the supplies to the affected orders.

Supply Planning

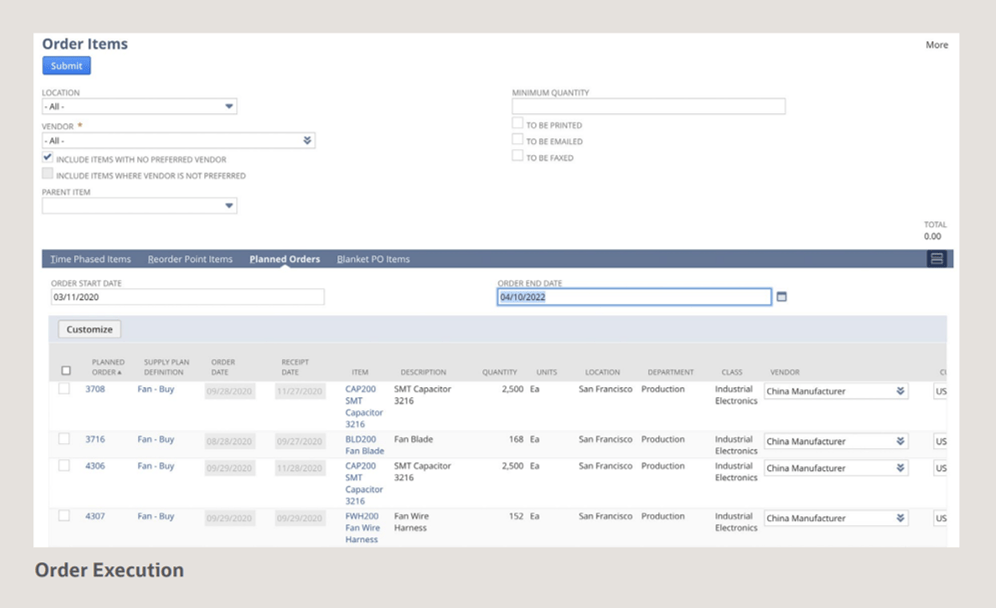

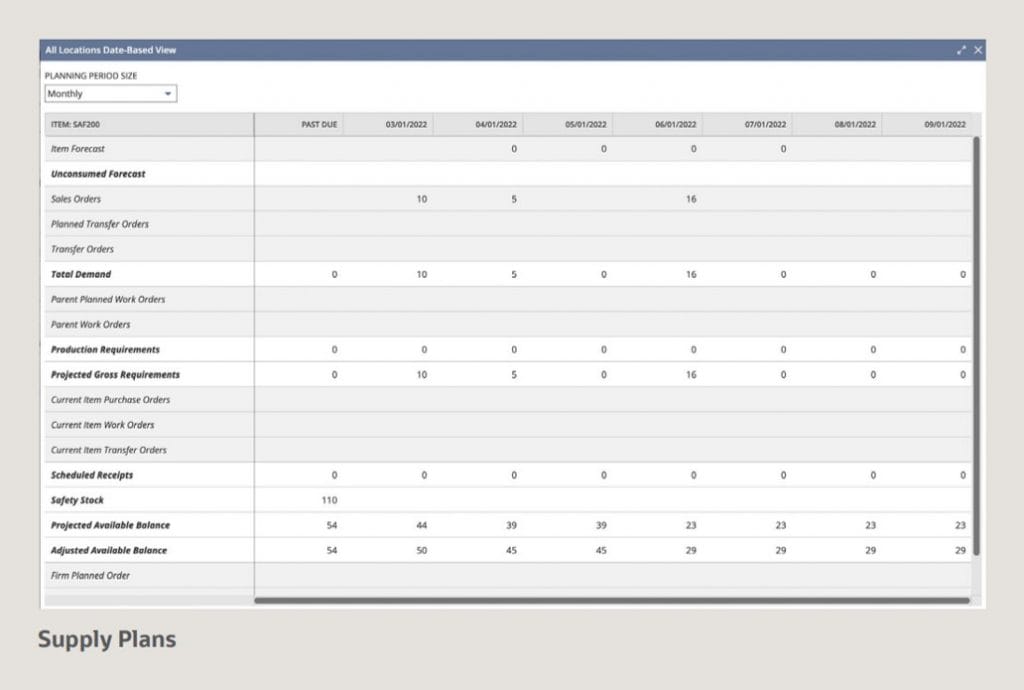

NetSuite Supply Planning determines how to best fulfill demand plan requirements to balance supply and demand and fulfill customer orders as promised. The objective is to balance supply and demand to achieve your organization’s financial and service objectives. Supply plans generate a recommended schedule for purchasing or manufacturing items and list the recommended purchase orders and work orders based on lead times and expected demand. This all ensures products are available to fulfill customer orders. NetSuite Supply Planning takes demand plans and generates them into purchase, work and transfer orders to ensure product is available to fulfill customer orders using three planning methodologies:

Reorder Points

Using Reorder Points, NetSuite generates a purchase order, work order or transfer order to restore inventory to the preferred stock level when it falls below the minimum threshold, referred to as the reorder point. When set to auto calculate, NetSuite will consider historical data values such as item demand from sales, lead time from the suppliers, and company-defined safety stock to define the reorder point.

Timed-Phased Planning

NetSuite Time-Phased Planning is used to plan demand when the repurchasing cycle is known. If a supplier always delivers on a particular day of the week, it makes sense to plan for this material based on the cycle in which it is delivered. In this case, NetSuite can calculate all supply needed to cover demand in the current cycle and it can be ordered and delivered together. You will not be able to reorder until the following delivery date.

Material Requirements

Planning NetSuite Material Requirements Planning, commonly referred to as MRP, gives businesses visibility into inventory requirements needed to meet demand, helping your business optimize inventory levels and production schedules. One of the standard methods for balancing supply and demand, NetSuite MRP accelerates the production process by determining what raw materials, components and subassemblies are needed, and when, to assemble finished goods based on demand and bill of materials (BOM). NetSuite MRP increases supply planning insight and efficiency, enabling businesses to efficiently manage inventory, schedule production, and deliver the right product—on time and at optimal cost.

What-If Scenario Planning

What-if analysis gives you the tools to understand how to best use your inventory. Using scenario planning, businesses can mock-up multiple scenarios and identify if it’s possible to speed up delivery by, for example, making changes to where goods ship from and when. With NetSuite MRP, you can set supply planning criteria, including the planning horizon, included items, locations and planning rules at the plan level vs. the item level. This allows businesses to build multiple hypothetical plans and run what-if scenarios to understand how changes will affect inventory levels and their ability to meet demand.

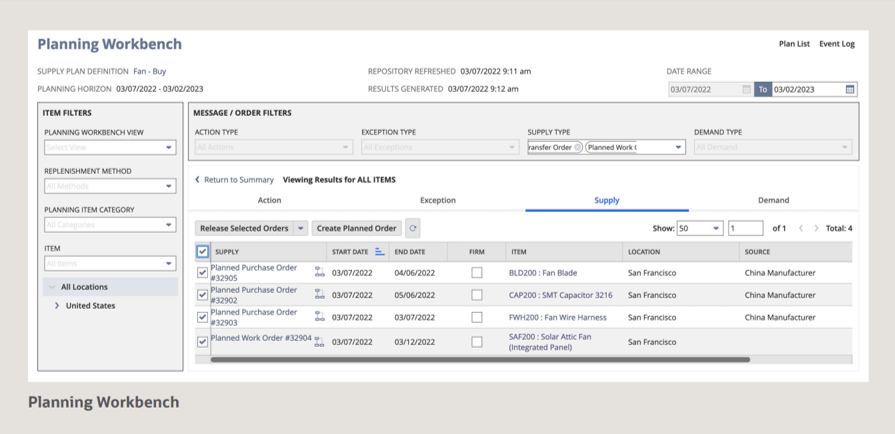

Planners Workbench

The Planners Workbench helps users highlight situations that require attention, allowing them to prevent both shortages and excess supplies, and provides what-if analysis capabilities for simulating multiple plans. By focusing on actions, exceptions, aggregation and execution, planners can monitor, firm up or release orders for approval and aggregation; review and accept action/exception messages individually or in bulk; and gain visibility into the allocation of demand to supply. The analysis is delivered in a logical layout that supports the decision-making process. NetSuite MRP offers full pegging support, so planners are also able to drill into supply and demand across locations for an item.

Supply Allocation

As a part of the supply allocation functionality, you’re able to allocate inventory that has already been received, and also inventory that you anticipate receiving, whether that’s on a work order, transfer order or purchase order. You’re also able to allocate inventory that’s coming in on an inbound shipment, which is basically a collection of purchase orders that are managed on an individual shipment basis. This allows customer service reps validate supply and identify the earliest date an order can be filled.

Allocation Exceptions Management

To respond to supply shortages and VIP customers, sources of supply and order allocations can be reviewed to ensure highest priority sales are fulfilled first. To minimize the effect on all orders, the system provides intelligent supply reallocation recommendations, designed to take the resources from multiple unallocated orders and fulfill priority orders first. System generated reallocation recommendations reduce the time to find, review and execute reallocations. After you accept a recommendation, the system automatically re-aligns the supplies to the affected orders. However, if the generated recommendations are not suitable, you can generate a new set of allocation recommendations. You can then review reallocation scenarios until you define a solution. After you approve an allocation, the system returns you to the order.