Ongoing supply chain disruptions and rising prices due to inflation mean many business leaders are hyper-focused on controlling inventory and understanding the impacts on cash flow and profitability of holding excess stock, or not having enough. If your needs are straightforward, you may be able to get by with a basic inventory management system. If, however, you stock, sell and fulfill items in more than one location, a system that provides visibility into stock levels across all your sites enables you to optimize your inventory and get products to customers the quickest and most cost-effective way possible.

Without a system in place to properly manage their inventory, enterprisewide, businesses run the risk of:

-

- Inefficient use of inventory: Too many items in one location, out of stock in another. It’s a classic problem arising when you’re unable to both view overall inventory levels across multiple locations AND move stock among sites cost-effectively. You run the risk of missing out on sales while incurring increased storage and handling fees.

- Higher COGS: When each site must order to ensure adequate stock levels and handle replenishment in a vacuum, you end up buying and holding more inventory overall, eating into profits. Worse, you may end up needing to offload unsold stock.

- Lost sales, lower customer satisfaction: When a customer returns a purchase in-store, sales associates have a window of opportunity to exchange the unwanted item for the correct size or a like product. However, without inventory visibility across all locations, the associate can’t provide the option for the customer to pick up a replacement item or have it shipped.

- Excess shipping: Without the ability to define where goods are shipped from, orders may be fulfilled from faraway locations. Given the rising cost of shipping, it’s a huge win to be able to specify the closest warehouse or adjust to avoid multiple shipments, which incur excess costs.

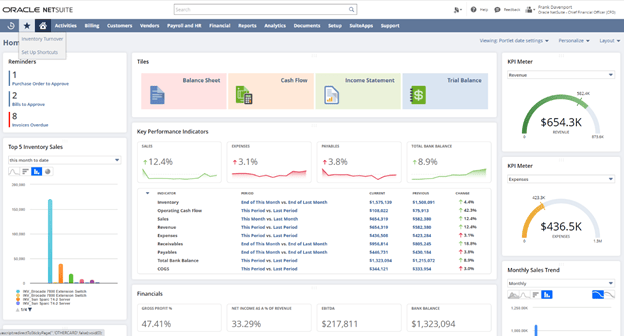

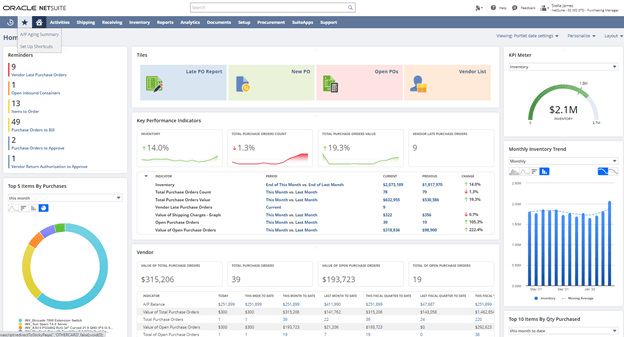

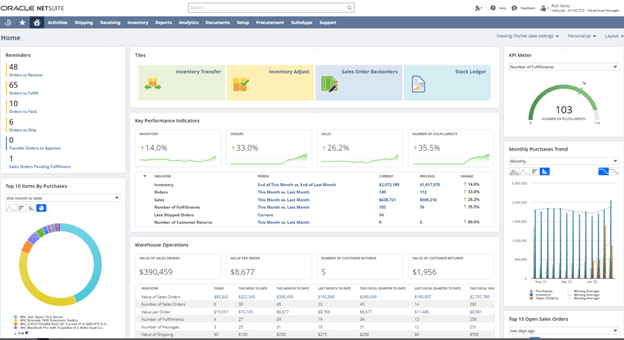

Visibility into real-time data allows businesses to eliminate all these problems and optimize inventory across all locations, efficiently manage stock and delight customers. Inventory dashboards provide that timely, at-a-glance rollup of the reporting, searches, key performance indicators and metrics meaningful to your business.

Role-specific dashboards further customize this data, providing key stakeholders with snapshots of your inventory standing tailored to their needs.

Top Role-Specific Dashboards

CFO dashboard: At an executive level, the dashboard provides a high-level understanding of overall business health and top KPIs, such as Inventory Value, Operating Cash Flow and COGS.

Purchasing manager: Dashboards specific to functional roles, such as the purchasing manager, provide a single location to manage daily tasks, such as monitoring open POs, reorder points and vendors.

Inventory/warehouse manager: Central to understanding and optimizing inventory usage across the organization, an inventory manager dashboard provides warehouse or inventory leads with essential information into fulfillment, stock allocations and inventory in transit.

6 Ways Dashboards Increase Profits

With this information, businesses not only have visibility into their stock levels but are equipped to increase profitability in some key ways:

- Maximize sell-through and minimize out-of-stocks. All your sites can be set up as locations in NetSuite, enabling a true enterprisewide view of inventory.

- Proactively monitor and balance stock levels. By transferring inventory between locations easily and efficiently, you ensure availability and minimize obsolete inventory.

- Minimize required inventory on hand. When you’re able to execute a cross-channel fulfillment strategy, easily fulfilling online orders from stores, you maximize the value of your locations and avoid excess stock.

- Gather valuable data. A dashboard helps buyers and other decision-makers analyze and understand seasonal and location-specific trends.

- Define fulfillment rules based on predefined parameters. By considering factors such as whole-order inventory availability and location, you can eliminate multiple shipments for a single order and the associated increased shipping charges.

- Save the sale in stock-out situations. With access to enterprisewide inventory availability, sales associates are empowered to transfer, hold or ship items directly to the customer.

Story by Abby Jenkins