The past year created a new sense of urgency among leaders of food manufacturing companies, and they’re making investments in technology and digital technologies as a result, according to a Manufacturing Leadership Council (MLC) poll. Supply chains are in sharp focus of course, with a majority re-evaluating their strategies because they experienced severe disruptions and want to better prepare for future events. One of those future events is sector growth. After hitting lows in March, manufacturing sentiment is climbing. In fact, 66% of respondents reported a positive outlook for their company, according to a Manufacturing Institute report. New functionality in NetSuite 2021 Release 1 will help manufacturing companies better predict demand and plan supply, adapt to the autonomous supply chain, and simplify inventory and warehouse management processes to drive down costs.

Autonomous Supply Planning Capabilities

- Enhancements to the Supply Planning Workbench now allow for date-based views so the planner can review the planning results for an item and location by period to uncover trends. There’s also a new sorting parameter called “high impact late demand threshold” that triggers a color-coded alert directly in the Supply Planning Workbench whenever late demand exceeds demand thresholds established by the company.

- To reduce strain on the system during busy times, planning repository refreshes can be automated to run in off hours. Planners can designate criteria for the process to repeat at a specific interval, freeing up their time as well.

- New Saved Search functionality provides ad-hoc reporting and analysis for planning repository data and the planning results data generated by the supply planning engine.

- Blanket PO schedules and inbound shipment information are now included in the snapshot view in Supply Chain Control Tower, which lends more accurate information on the projected net available inventory balance for each location.

Automated Inventory Management

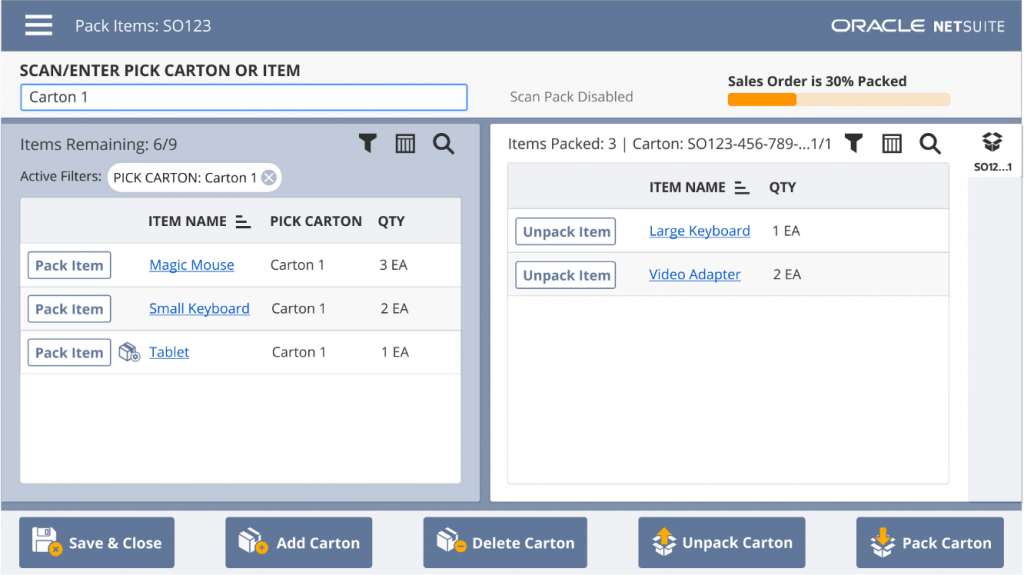

- The new NetSuite Pack Station provides a simple, touchscreen interface for easier and more accurate packing processes. Some of the new functionality includes grouping orders with the same shipping routes together so those orders can be packed together, support for partial picking and weights can be scanned directly from scales, to avoid errors from manual entry.

- New warehouse management system (WMS) enhancements provide the ability to automatically create picking waves and organize by delivery times, delivery address, shipment numbers and more. Wave creation activities can be scheduled for off-peak hours so that the system isn’t taxed during busy periods. Other enhancements focus on tally scans, cart put-away, bulk picking, automatic label printing and added support of mobile status changes.

- Inventory can be allocated and reserved by channel and manufacturers can now allocate against a blanket PO.

- Customers can configure rules for FEFO (first expiry, first out) allocation of inventory to optimize inventory and reduce waste.

Smart Financials and Operational Automation

- New functionality better supports invoicing and billing processes for multiple subsidiaries by automating the process of moving the items from a single PO from the purchasing subsidiary to the one they’re going to, previously a highly manual process. Statutory bills and paperwork required for each individual subsidiary is also now automated.

- New expense commitments and budget validation functionality prevents overspending by validating purchase requests and orders against an organization’s available budget, ensuring that budgets are closely followed.

Text by Gavin Davidson